Clean Room Qualification

- Home

- Clean Room Qualification

Clean Area Qualification

All Clean room Qualification Service results are thoroughly documented and quality-reviewed in accordance with the rigors of cGMP.

Clean room test protocols and report documentation can be customized to customer specifications.

Cleanroom Validation/HVAC Validation is performed for a variety of reasons. To ensure that the design of the facility is fit for its intended purpose; to ensure that the facility, equipment, and environment meets User Requirement Specifications (URS); to ensure that the facility, equipment, and environment meet defined regulatory requirements; to ensure that the facility, equipment, and its environment function together as a system to meet defined standards.

Clean Area Qualification / HVAC System Services Scope

Airflow velocity test

We conduct Air Velocity Measurement / tests to determine the average filter face velocity and uniformity for Terminal HEPA filter within a clean room or in Laminar air flow units. The use of TSI Hotwire anemometer , assures accurate test results.

Air flow volume and Room air change rates

We conduct Air Flow Measurement / tests to determine air flow volume within a clean room. Air Exchange Rate tests determine the total air volume get in to the room within a clean room. The use of Air Capture Hoods , assures accurate test results. The hood measures air volume flowing through registers, diffusers and grills.

Airflow velocity test

We conduct Air Velocity Measurement / tests to determine the average filter face velocity and uniformity for Terminal HEPA filter within a clean room or in Laminar air flow units. The use of TSI Hotwire anemometer , assures accurate test results.

Temperature and Relative humidity measurements

We conduct validation tests that include Temperature and Humidity Measurements / Tests. temperature and humidity uniformity are tested to ensure that the clean room's HVAC system maintains the specified levels of temperature and humidity required for occupant comfort and process temperature control.

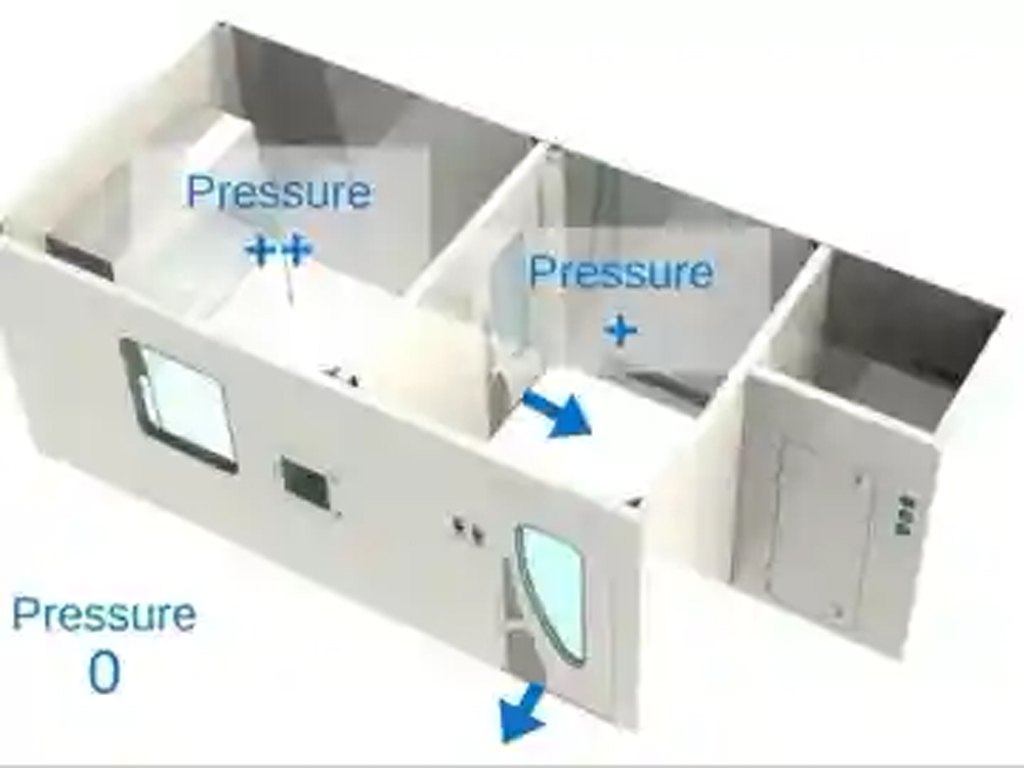

Air Pressure Difference between rooms

We conduct Room Pressurization Test for industrial clean rooms. As a part of the validation process, this test verifies that a pressure differential meet the specified requirements.

Non-viable particulate Counting

We are EESS a reputed name in offering clean room validation services. Our Particle Count Test provides complete airborne particle count cleanliness classification. The test is performed to determine the actual particle count level within the facility at the time of the test. The test identifies particle count on basis of As-Built, At-Rest, or Operational as per ISO 14644 , EU GMP . The particle size(s) of interest, the room occupancy state and the room classification shall be known prior to the

Laminar Air Flow Unit Qualification

EESS has the total capability to perform all the following tests, each with it’s respective international standard for Laminar Air Flow Unit , Biohazard Safety Cabient , Fume hood , and Air Shower. HEPA Filters Leak Test (Integrity Test). Air Velocity Test. Airborne Particle Counting. Airflow Visualization Studies (Smoke Test). Recovery Time Test and more.

Recovery time test

We execute recovery tests for clients across Industries. These tests demonstrate the ability of the clean room to remove particulate by purging the area with filtered air. It also testifies if the room can change from a "dirty" to "clean" state within the specified time. The test is conducted by experienced technicians from team. Our technicians have enriching experience and provide clients with high quality service. The ultimate goal of our company is to assure complete satisfaction of clients

Airflow visualization testing

EESS offer Airflow Visualization Test as a part of the validation process. The purpose of the airflow visualization test is to show the actual airflow pattern throughout the unidirectional clean room. The test can also be used to demonstrate the effects on airflow caused by equipment. It is best to perform this test after all airflow velocity and uniformity tests and room pressurization tests have been performed. The test determining the airflow patterns within a room using ISO 14644 guides